The Semiconductor Market For Used Equipment

In this edition of the Semiconductor And Beyond Newsletter newsletter, let us focus on the often-overlooked yet critical aspect of the semiconductor industry - the used equipment market. As companies seek cost-effective and sustainable manufacturing solutions, understanding the dynamics of used equipment, its benefits, challenges, and how to leverage this market effectively can be a game-changer for businesses and professionals. Let us explore what used equipment entails, the types available, market trends, and resources to help you navigate this niche yet vital segment of the semiconductor ecosystem.

What Is Used Equipment In The Semiconductor Industry?

Used equipment in the semiconductor industry refers to previously owned tools and machinery that have been refurbished, reconditioned, or resold for continued manufacturing. This equipment, purchased initially new by semiconductor companies, includes a wide range of tools such as lithography systems, etchers, deposition equipment, test handlers, and inspection systems.

After being decommissioned by the original user, the equipment undergoes a rigorous process of cleaning, testing, and sometimes upgrading to meet current industry standards. This ensures that the refurbished equipment is of high quality and reliable, making it a cost-effective solution for companies, especially those with budget constraints or start-ups, to ramp up production quickly.

Why Consider Used Equipment?

In the highly capital-intensive world of semiconductor manufacturing, the cost of setting up and maintaining production facilities can be a daunting challenge. This is where used equipment steps in as a strategic solution. Opting for pre-owned machinery offers numerous advantages, from significant cost savings to quicker deployment times, making it an appealing choice for companies aiming to stay competitive without compromising quality and efficiency. Let's explore why used equipment has become an innovative and sustainable option for many in the semiconductor industry.

Cost Savings:

Purchasing used equipment can significantly reduce capital expenditure, often costing 30-70% less than new equipment. This is critical for smaller companies and new fabs looking to optimize their budgets.

Reduced Lead Time:

Unlike new equipment, which can have extended lead times due to manufacturing and customization, used equipment is readily available. This allows companies to quickly set up or expand production lines, responding swiftly to market demands.

Proven Reliability:

Used equipment has a track record of performance in actual manufacturing environments. This can provide confidence in its reliability and stability, mainly when sourced from reputable suppliers who refurbish and certify the equipment.

Flexibility and Availability:

The used equipment market offers various tools, including older models that may not be available as new. This can be particularly useful for manufacturers who maintain or expand existing production lines without costly upgrades.

Sustainability:

Reusing equipment supports sustainable manufacturing practices by extending the machinery lifecycle, reducing electronic waste, and conserving resources needed to produce new equipment.

Accessibility for Emerging Markets:

For semiconductor companies in emerging markets or regions with less access to capital, used equipment provides a viable entry point to compete in the global market.

Incorporating used equipment into your semiconductor manufacturing strategy can unlock significant value, whether looking to reduce costs, speed up production, or enhance sustainability. While it's essential to carefully assess the condition and compatibility of used tools, the benefits often outweigh the challenges. For companies that balance performance with budget constraints, used equipment offers a viable pathway to achieving operational excellence in a dynamic and demanding market.

Types Of Used Semiconductor Equipment

These various types of used semiconductor equipment provide manufacturers with flexible and cost-effective options to optimize their production processes, enabling them to efficiently meet both technical and financial requirements.

Front-End Equipment:

Lithography Machines: These are used for patterning intricate circuits onto silicon wafers, including tools like step-and-scan systems and mask aligners.

Etching Systems: Essential for removing material from the wafer to create the desired circuit patterns, including dry etchers and wet etchers.

Deposition Tools: Equipment for adding thin films onto wafers, such as chemical vapor deposition (CVD), physical vapor deposition (PVD), and atomic layer deposition (ALD) systems.

Back-End Equipment:

Test Handlers: Used to automate the handling of semiconductor devices during testing processes, ensuring high throughput and accuracy.

Die Bonders: Machines that attach individual semiconductor chips to their packages or substrates, which are crucial in assembly.

Wire Bonders: Equipment that connects the die to the package using fine wires, a critical step in semiconductor packaging.

Metrology and Inspection Equipment:

Scanning Electron Microscopes (SEMs): Utilized for detailed imaging and analysis of wafer surfaces, which is crucial for quality control.

Defect Inspection Systems: Tools designed to detect and classify defects on wafers, ensuring that only high-quality products proceed to the following manufacturing stages.

Profilometers: Instruments used to measure surface profiles and film thicknesses, providing critical feedback for process optimization.

Wafer Probers:

Equipment used to test the electrical properties of wafers by making temporary contact with the semiconductor die is often a precursor to final testing in the back-end process.

Assembly and Packaging Equipment:

Molding Machines: Used to encapsulate the semiconductor die in protective plastic, ensuring the durability and reliability of the final product.

Trim and Form Systems: Machines that trim excess material and shape the package leads to fit into circuit boards.

Benefits And Challenges

Using used equipment in the semiconductor industry offers several compelling benefits. One of the primary advantages is cost efficiency; used tools can be significantly cheaper than new ones, allowing companies to optimize their capital expenditure. Additionally, pre-owned equipment is typically available immediately, enabling rapid deployment and capacity expansion without the long lead times associated with new machinery. This is particularly advantageous for companies looking to respond quickly to market changes.

Furthermore, used equipment often comes with a proven track record of performance, providing a level of operational reliability that new, untested tools may lack. However, a key benefit that should not be overlooked is sustainability. Reusing equipment reduces the need for new manufacturing, conserving resources and minimizing environmental impact. This can be a significant selling point for companies in emerging markets or startups with limited budgets, allowing them to compete on a global scale.

However, there are challenges to consider. Compatibility and obsolescence can be significant issues, as older equipment may need to integrate better with newer technologies or processes, and its remaining operational life might be shorter. Support and documentation can also be limited, especially if the original manufacturer no longer offers service or spare parts for the equipment. Quality and condition can vary widely, posing a risk of hidden defects that may lead to unexpected downtimes and increased maintenance costs.

Additionally, older equipment might need to meet current regulatory or safety standards, necessitating costly modifications or upgrades to comply. Finally, the availability of specific tools can be unpredictable, making it difficult to find exact matches for particular manufacturing needs. Despite these challenges, with careful evaluation and strategic use, the benefits of used semiconductor equipment can outweigh the drawbacks, providing a valuable option for companies looking to enhance their production capabilities cost-effectively.

Market Outlook

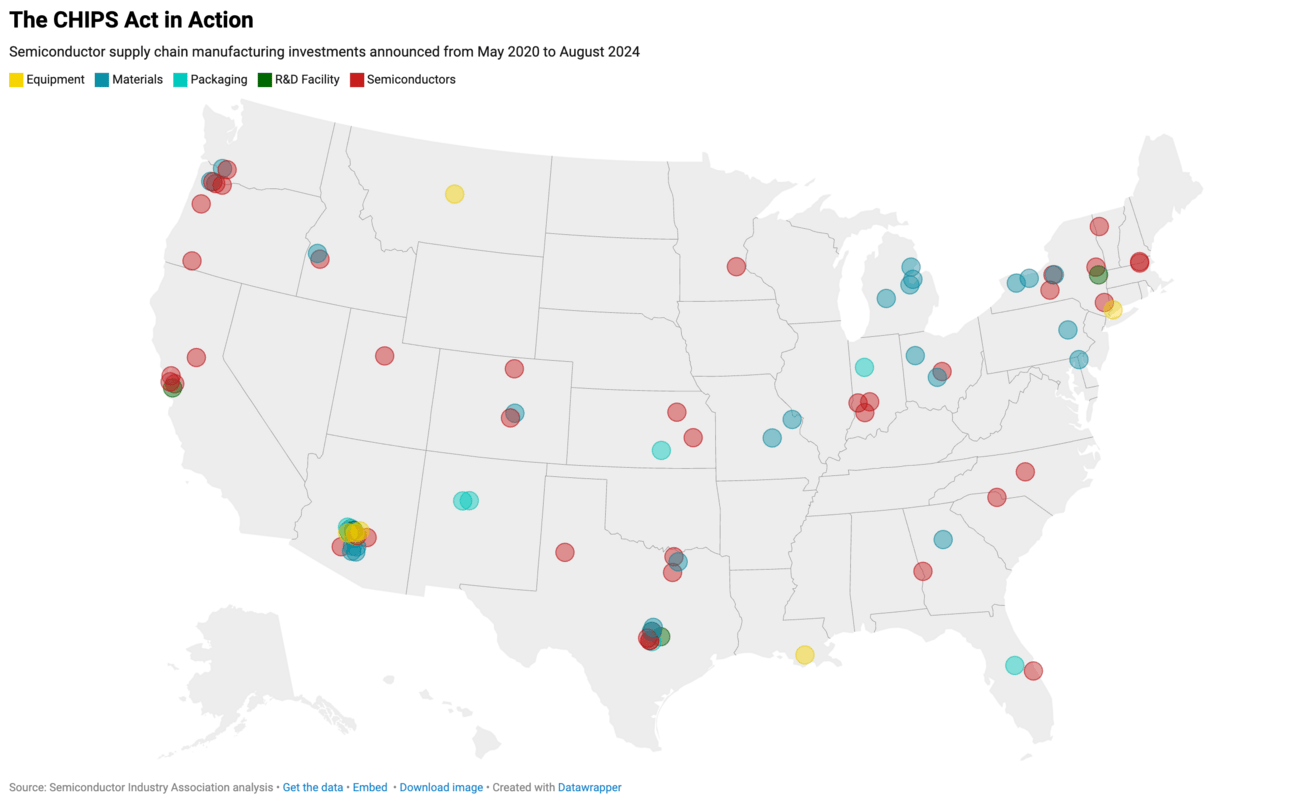

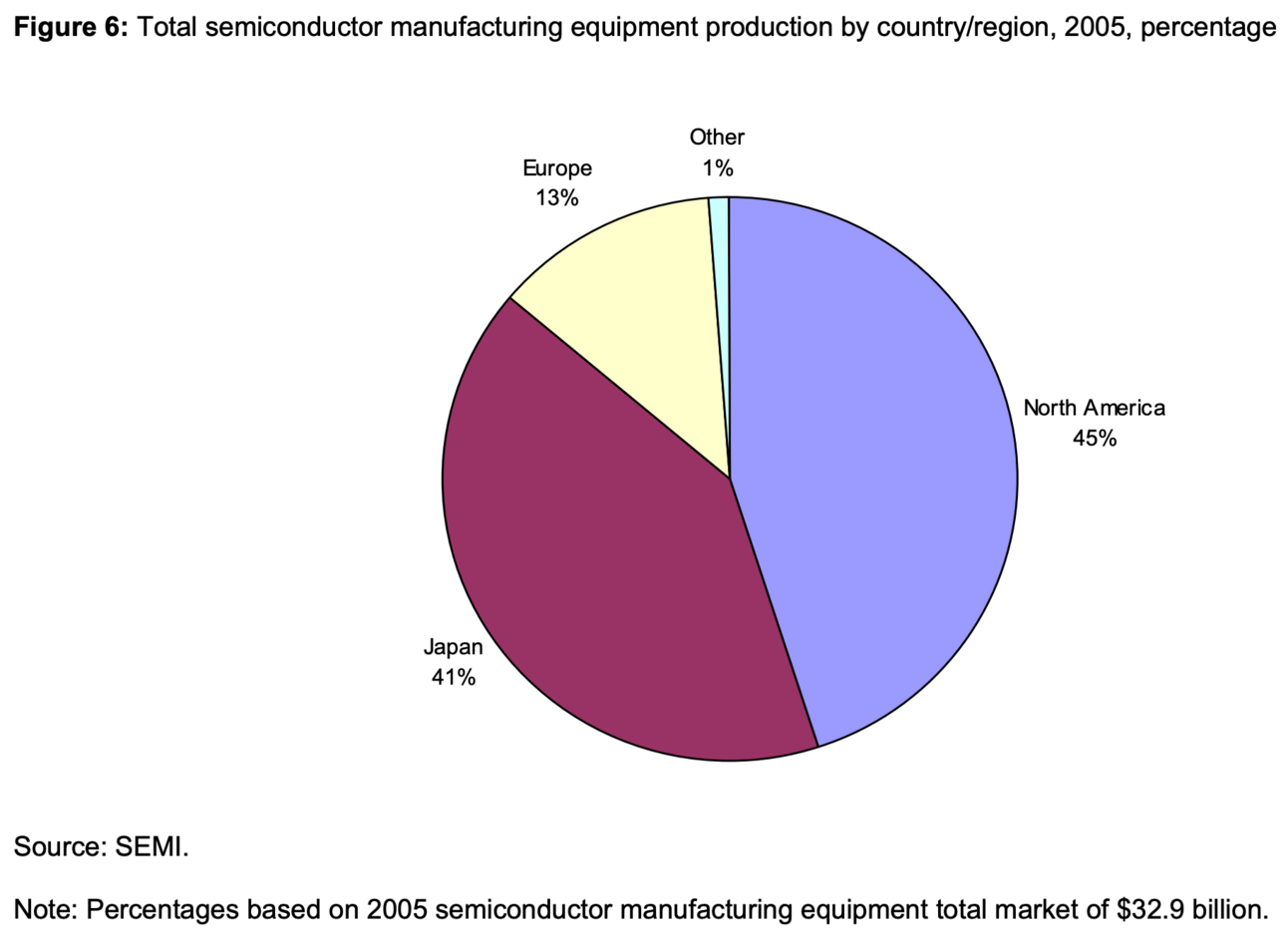

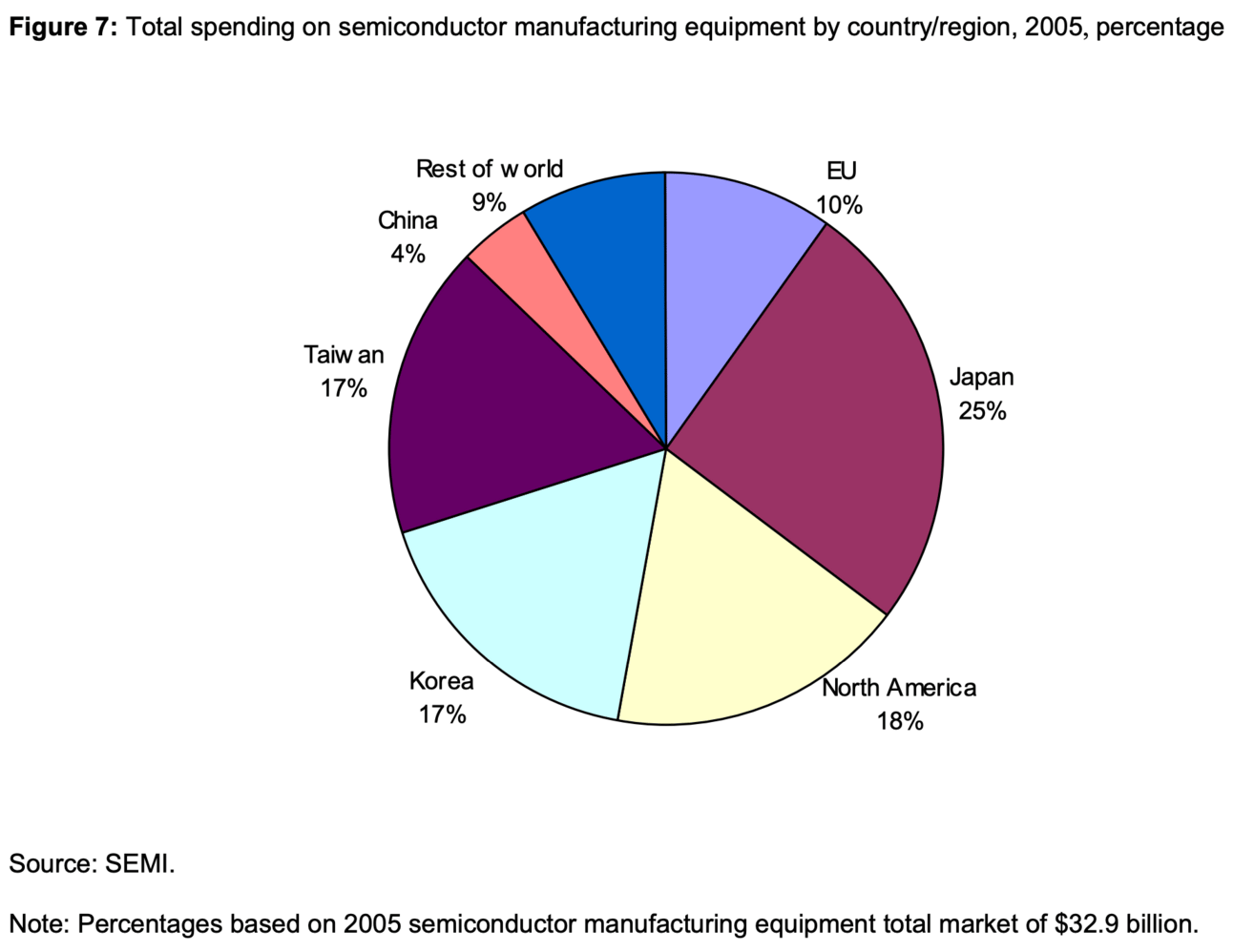

The global market for used semiconductor equipment is projected to grow significantly, reaching an estimated $19.9 billion by 2031, up from $12.9 billion in 2023, with a compound annual growth rate (CAGR) of around 7%. This growth is driven by several factors, including the need for cost-effective manufacturing solutions, rapid technological advancements, and the increasing demand for semiconductors across various industries, such as consumer electronics, automotive, and industrial applications.

The Asia-Pacific region leads the market, accounting for approximately 68% of the global share. Countries like China, Taiwan, South Korea, and Japan are significant hubs for semiconductor manufacturing, creating a high demand for new and used equipment. In particular, China's substantial investment in advanced computing infrastructure and its focus on expanding semiconductor production capacity are critical drivers of this demand. The availability of used equipment in the region is further supported by an established refurbishment infrastructure, a testament to the reliability and sustainability of the market, which helps companies manage costs while maintaining production capabilities.

One of the primary segments in this market is wafer fabrication equipment, which accounted for the largest share in 2023. This segment's dominance is due to the high cost of new wafer fabrication tools, which makes used options an attractive alternative for companies looking to manage capital expenses. The rapid technological advancements in this sector not only contribute to the frequent availability of used equipment but also promise an exciting future for the industry as manufacturers upgrade to newer models.

Overall, the used semiconductor equipment market offers a valuable opportunity for companies to optimize costs and remain competitive, especially in a dynamic and evolving industry landscape.

Take Aways

The used semiconductor equipment market is a cost-effective solution for manufacturers, helping balance budget constraints while maintaining production efficiency. It plays a crucial role in extending the life cycle of expensive machinery like wafer fabrication tools, offering companies significant savings and promoting sustainability by reducing e-waste.

Despite technological obsolescence and quality concerns, the market thrives, especially in regions with solid refurbishment infrastructures. For businesses in the semiconductor sector, used equipment presents a strategic option that supports economic and environmental goals.

CONNECT

Whether you are a student with the goal to enter semiconductor industry (or even academia) or a semiconductor professional or someone looking to learn more about the ins and outs of the semiconductor industry, please do reach out to me.

Let us together explore the world of semiconductor and the endless opportunities:

And, do explore the 200+ semiconductor-focused blogs on my website.