The Value And Cost Of Semiconductor Data

Semiconductor data is a vital yet costly resource. Unlike other data types, it requires significant financial investments to generate and maintain. Today, let us explore the economic impact of semiconductor data generation, supported by real-world examples and statistics.

What Is Semiconductor Data: It encompasses a wide range of information, including diffusion process data, assembly data, test data, and yield data. This data is essential for ensuring the quality, efficiency, and reliability of semiconductor products. For example:

Diffusion Process Data: Information on how materials are diffused in semiconductor wafers

Assembly Data: Details on the assembly of semiconductor components into final products

Test Data: Results from testing semiconductor devices to ensure they meet required specifications

Yield Data: Statistics on the number of functional devices produced from a batch of semiconductor wafers

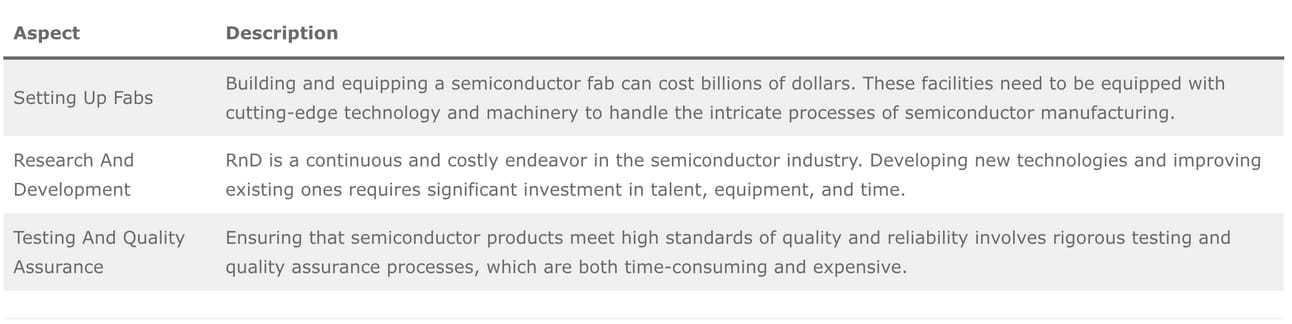

Generating this data involves a series of complex and expensive processes. From setting up state-of-the-art fabrication plants (fabs) to conducting extensive research and development, the costs add up quickly.

For instance:

Understanding The Economics Of Semiconductor Data

The generation of semiconductor data is not just a technical challenge but also a significant economic endeavor. The costs associated with obtaining high-quality data for semiconductor processes are immense, impacting both the industry and the broader economy. To understand this impact, it is essential to look at the financial investments required and the economic benefits that follow.

Statistics-Based Analysis:

Infrastructure Investment:

Intel in Chandler, AZ: Invested $32 billion, creating 3,000 jobs, for two new fabs. This highlights the significant upfront costs involved in setting up semiconductor manufacturing facilities.

TSMC in Phoenix, AZ: Invested $65 billion, creating 6,000 jobs, for three new fabs. This investment underscores the massive financial commitment required to expand semiconductor manufacturing capabilities.

Research And Development Costs:

According to a report by Semiconductor Industry Association (SIA), global semiconductor RnD spending reached approximately $71.4 billion in 2020. This demonstrates the continuous and substantial investment required for innovation and maintaining competitive advantage in the industry.

Testing And Quality Assurance:

The cost of testing and quality assurance in semiconductor manufacturing can account for up to 30% of the total manufacturing cost. This significant expenditure is necessary to ensure the reliability and performance of semiconductor products

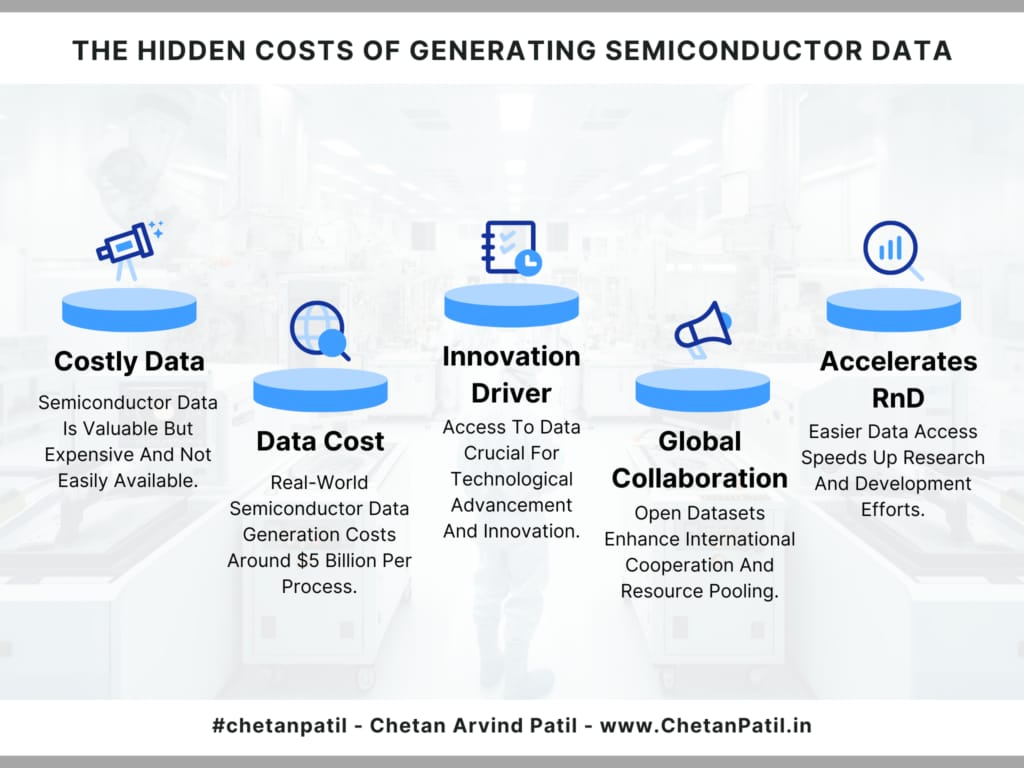

Picture By Chetan Arvind Patil

Connecting Expense With Yield Data Generation:

Yield Data Generation:

Yield data, which refers to the proportion of functional semiconductor devices produced from a batch of wafers, is critical for assessing and improving manufacturing processes.

Economic Impact:

Improved yield data can lead to higher production yields, reducing the cost per unit and increasing profitability. For instance, if a fab can increase its yield from 80% to 90%, it can produce more functional devices from the same number of wafers, enhancing overall efficiency and profitability.

Read more....

CONNECT

Whether you are a student with the goal to enter semiconductor industry (or even academia) or a semiconductor professional or someone looking to learn more about the ins and outs of the semiconductor industry, please do reach out to me.

Let us together explore the world of semiconductor and the endless opportunities:

Website: https://www.ChetanPatil.in

Twitter: https://twitter.com/iChetanPatil

Instagram: https://www.instagram.com/ChetanArvindPatil